Page 21 - Beverage MasterOct Nov 2020

P. 21

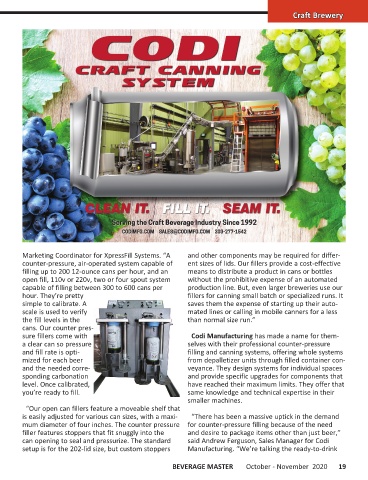

Craft Brewery

Marketing Coordinator for XpressFill Systems. “A and other components may be required for differ-

counter-pressure, air-operated system capable of ent sizes of lids. Our fillers provide a cost-effective

filling up to 200 12-ounce cans per hour, and an means to distribute a product in cans or bottles

open fill, 110v or 220v, two or four spout system without the prohibitive expense of an automated

capable of filling between 300 to 600 cans per production line. But, even larger breweries use our

hour. They’re pretty fillers for canning small batch or specialized runs. It

simple to calibrate. A saves them the expense of starting up their auto-

scale is used to verify mated lines or calling in mobile canners for a less

the fill levels in the than normal size run.”

cans. Our counter pres-

sure fillers come with Codi Manufacturing has made a name for them-

a clear can so pressure selves with their professional counter-pressure

and fill rate is opti- filling and canning systems, offering whole systems

mized for each beer from depalletizer units through filled container con-

and the needed corre- veyance. They design systems for individual spaces

sponding carbonation and provide specific upgrades for components that

level. Once calibrated, have reached their maximum limits. They offer that

you’re ready to fill. same knowledge and technical expertise in their

smaller machines.

“Our open can fillers feature a moveable shelf that

is easily adjusted for various can sizes, with a maxi- “There has been a massive uptick in the demand

mum diameter of four inches. The counter pressure for counter-pressure filling because of the need

filler features stoppers that fit snuggly into the and desire to package items other than just beer,”

can opening to seal and pressurize. The standard said Andrew Ferguson, Sales Manager for Codi

setup is for the 202-lid size, but custom stoppers Manufacturing. “We’re talking the ready-to-drink

BEVERAGE MASTER October - November 2020 19

BM080920 Main Pages copy.indd 19 9/28/20 1:50 PM