Page 21 - Beverage MasterFebMarch 2021_Update

P. 21

Craft Brewery

basis and wants to see a greater ROI on canning

expense,” said Davis and Pirog. “This canning line is

best coupled with automated upstream and down-

stream equipment to accommodate the faster

speeds. This line comes standard with a buffer tank

to help manage product feed from bright tanks.”

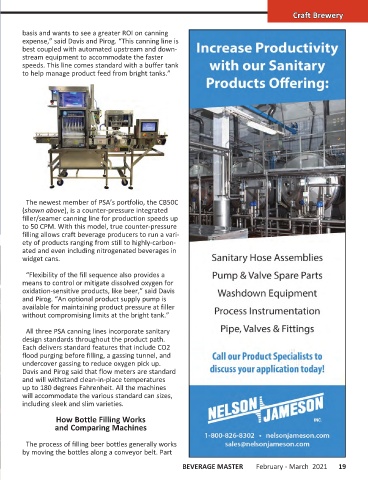

The newest member of PSA’s portfolio, the CB50C

(shown above), is a counter-pressure integrated

filler/seamer canning line for production speeds up

to 50 CPM. With this model, true counter-pressure

filling allows craft beverage producers to run a vari-

ety of products ranging from still to highly-carbon-

ated and even including nitrogenated beverages in

widget cans.

“Flexibility of the fill sequence also provides a

means to control or mitigate dissolved oxygen for

oxidation-sensitive products, like beer,” said Davis

and Pirog. “An optional product supply pump is

available for maintaining product pressure at filler

without compromising limits at the bright tank.”

All three PSA canning lines incorporate sanitary

design standards throughout the product path.

Each delivers standard features that include CO2

flood purging before filling, a gassing tunnel, and

undercover gassing to reduce oxygen pick up.

Davis and Pirog said that flow meters are standard

and will withstand clean-in-place temperatures

up to 180 degrees Fahrenheit. All the machines

will accommodate the various standard can sizes,

including sleek and slim varieties.

How Bottle Filling Works

and Comparing Machines

The process of filling beer bottles generally works

by moving the bottles along a conveyor belt. Part

BEVERAGE MASTER February - March 2021 19

BM020321 Main Pages copy.indd 19 1/22/21 2:31 PM