Page 11 - Beverage Master_JuneJuly 2021

P. 11

Craft Brewery

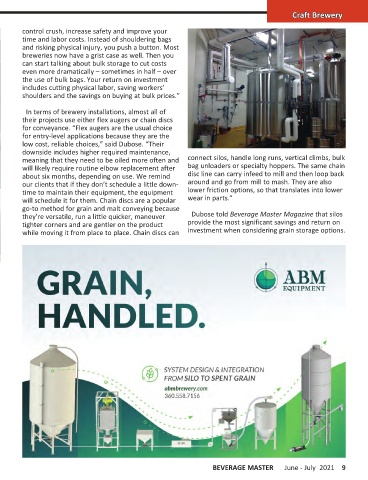

control crush, increase safety and improve your

time and labor costs. Instead of shouldering bags

and risking physical injury, you push a button. Most

breweries now have a grist case as well. Then you

can start talking about bulk storage to cut costs

even more dramatically – sometimes in half – over

the use of bulk bags. Your return on investment

includes cutting physical labor, saving workers’

shoulders and the savings on buying at bulk prices.”

In terms of brewery installations, almost all of

their projects use either flex augers or chain discs

for conveyance. “Flex augers are the usual choice

for entry-level applications because they are the

low cost, reliable choices,” said Dubose. “Their

downside includes higher required maintenance,

meaning that they need to be oiled more often and connect silos, handle long runs, vertical climbs, bulk

will likely require routine elbow replacement after bag unloaders or specialty hoppers. The same chain

about six months, depending on use. We remind disc line can carry infeed to mill and then loop back

our clients that if they don’t schedule a little down- around and go from mill to mash. They are also

time to maintain their equipment, the equipment lower friction options, so that translates into lower

will schedule it for them. Chain discs are a popular wear in parts.”

go-to method for grain and malt conveying because

they’re versatile, run a little quicker, maneuver Dubose told Beverage Master Magazine that silos

tighter corners and are gentler on the product provide the most significant savings and return on

while moving it from place to place. Chain discs can investment when considering grain storage options.

BEVERAGE MASTER June - July 2021 9

BM060721 Main Pages.indd 9 5/21/21 9:59 AM