By: Kary Shumway and Andrew Coplon from TaproomSuccess.com

In sports you need a scoreboard to understand if your team is winning or losing. The same holds true for measuring the financial and operational results of your taproom. You need a scorecard to keep track.

In this article we’ll walk through the steps to create scorecards for your taproom so that you can measure and improve outcomes. It’s not difficult, and it can transform your taproom financial results.

Let’s start with some basics: What is the point of the scorecard?

The purpose of a scorecard is to show the goal or goals you most want to accomplish. It can be as flexible as you like. It can present financial or non-financial numbers. It is designed to capture and quantify your most important numbers.

The scorecard should:

1. Keep the goals front and center every day

2. Be only one page (or one number) so that it’s easy to see how you’re doing at a glance

3. Use numbers (key metrics) to communicate

the goal

First: Measure the Most Important Thing(s)

Deep inside, we all know what the most important thing really is. Whether it is in our taproom business or in our life, we know what it is. The problem is that we forget.

The most important thing is remembering the most important thing. The scorecard helps you identify what is most important and remember it every day.

It is a simple tactic, but very effective if you follow it. The scorecard provides focus on how you’re doing towards what’s most important.

How to Figure Out the Most Important Thing

If you are struggling to figure out what is most important, try a few focusing questions:

● What keeps you up at night?

● What is the biggest opportunity to take advantage of?

● What is the biggest problem you need to fix?

Here’s Kary’s story…cash keeps him up at night. More specifically, running out of cash!

So, Kary designed a one-page scorecard to monitor our business cash position every day. It shows the bank balances, borrowing balances, upcoming spending and expected receipts. It shows borrowing ability and future cash needed to fund growth.

The cash scorecard helps Kary sleep better at night because he’s focusing on the most important thing.

Figure out what your One Thing is, measure it, and put it on a scorecard.

The Process to Communicate & Educate

The scorecard alone won’t achieve the goal. You need to take action to get things done. Often, you need action by your managers and employees – your team.

The process below is an effective way to communicate anything you like, and it works well with the taproom scorecard:

1. Know the Score. To know the score, you have to SHOW the score. Don’t play hide and seek with your scorecard or bury it in a desk drawer. Share it with those that can help you win.

2. Educate your Team. Teach your managers and employees how the scorecard works and how they can make a difference. People want to contribute, teach them how.

3. Set a Goal to Improve. Use your past performance + set a goal to do better.

4. Monitor the score, track Progress. Provide regular updates or people lose interest.

5. Celebrate the win. Free beer works well when you hit the goal!

Taken together, the 5 steps presented above are an effective method to make sure you get the most out of your taproom scorecard and achieve your goals.

Use Process and Outcome Metrics

We are a results-oriented society. We like to get stuff done.

However, it is useful to focus on the Process of getting stuff done in addition to the results or the Outcome. The idea here is to use “Process and Outcome Metrics” on the scorecard.

Process means the action taken, or steps that need to be followed. We can’t always control the outcome, but we can control actions, effort, following a prescribed routine.

For example: Teach your taproom staff to ask for the sale and offer an item to upsell.

Teach them to ask for the customer’s email so you can tell them about new beers or special releases. Send out marketing emails and make social media posts on a regular basis. These are things you do to drive sales, increase profits, or achieve the most important thing.

Outcome means the actual results. The Outcome is a by-product of actions. If you’re not getting the results you want, experiment with the actions.

Consider measuring both Process and Outcome goals on your scorecard. We all measure the result, but sometimes we need to measure (and reward) the process to get there.

Scorecard Templates

There are different scorecards for different needs. For example, if you want to increase taproom sales, the scorecard will show key metrics to achieve that goal. If you want to improve the customer experience and satisfaction, you can create metrics to support that goal as well.

Below, are three types of taproom scorecards:

1. Sales Focused Scorecard

2. Engagement Scorecard

3. Motivation Scorecard

#1 The Sales Focused Scorecard: As the name implies, the Sales Focused Scorecard is laser focused on key metrics to support sales.

Typical Key Metrics to support sales:

● Total Sales $ / by day / week / month

● Sales by category / product / service

● Sales per BBL

● Customers per day / week / month

● Average ring per customer

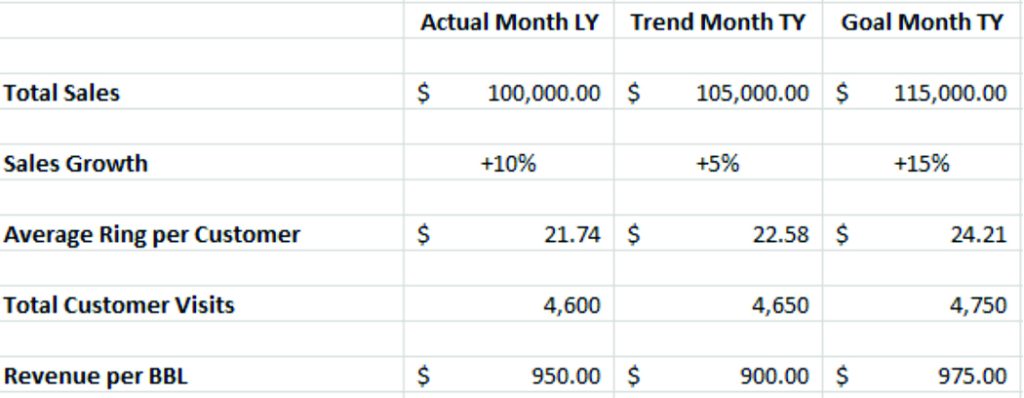

The Chart below shows an example of the Sales Focused Scoreboard:

The Actual Month LY (last year) column presents the results from the same month last year. The Trend Month TY (this year) column presents where we are currently, and how sales are trending. The Goal Month TY shows what we want to achieve this month.

In summary, the scorecard shows the type of metric to measure. It shows where we’ve been (past results), where are now (current results), and where we want to be (the goal).

#2 The Engagement Score: This scorecard combines similar elements of the Sales Scorecard, but takes a greater focus on how well your staff is building relationships with your guests. Your ability to understand the below engagement metrics can result in improvements on your sales metrics.

Typical Key Metrics to monitor engagement:

● Tip percentage

● Flight sales

● Tab size

● To go beer sales

Your team members’ average tip amount correlates directly with their level of engagement. We see the staff member that offers a high level of engagement receive an average tip of 27.1% vs a staff member that offers a low level of engagement only seeing an average tip of 24%.

While flight sales may not be an obvious sign of engagement, flights are an opportunity for a staff member to educate a guest further about your beers, and brewery. When staff suggest a flight, guests spend an average of 20% more, and also a tip a point higher.

Additionally, because a staff member providing a higher level of engagement is seeking to build a deeper relationship with their guests, they are by default more likely to include more upsell opportunities in their interactions (i.e. suggested additional beverages, to go beers). This results in not only higher tabs, but also more meaningful connections. These guests are more likely to recommend your brewery to others and return sooner.

#3 The Motivation Scorecard: This is a staff-specific scorecard. As a manager or brewery owner, the more successful you are at understanding your team’s needs, the better you will be able to motivate them.

When you are able to create successful

strategies to motivate your staff, you will see:

● Greater passion from your staff

● Greater teamwork

● Higher tabs

● Higher retention

● Your job becomes easier

● Greater taproom success

But what metrics can you monitor to gauge how well you are motivating your team?

Typical Key Metrics to support motivation:

● Frequency of rewards

● Frequency of recognition

● Frequency of team meetings and trainings

● Growth opportunities

● Length of employment

While offering your team fair base pay is where to begin, it is also important to regularly reward your staff for a job well done. Motivation isn’t a one-time to go beer sales content. Motivation is finding a plethora of metrics, many from the lists above, that you can use to track and reward your team’s performance. The number and frequency of reward opportunities will correspond with how well your team is motivated.

Through conversations with your staff, you will learn that some people are motivated by rewards, while others may be motivated by recognition. Your repertoire should include both physical rewards and recognizing team members who hit specific goals.

While it is important to regularly reward and recognize your team for desired behaviors, hosting regular meetings and trainings is vital to provide them with the skills for success. These are opportunities for you as a manager or owner to connect with your team. The more your team feels connected, the more motivated they will be to work together for organizational goals.

Increases in your team’s average duration of employment at your brewery correlates directly to the quality of their experience, and thus how well you are motivating them. Length of employment can also represent you offering staff the opportunity to grow with your company. This could come in the form of offering staff educational/certification opportunities, or providing them the ability to climb in rank at your brewery.

Wrap Up and Action Items

The taproom scorecard is a powerful tool to help you increase the sales and profitability of your taproom. It measures the most important thing, the most important goal(s), and keeps it in front of your team every day.

To get started with your taproom scorecard, determine your most important thing. Maybe it’s growing sales, profitability, or customer satisfaction. Whatever is most important, get it on the scorecard, and set a goal to achieve it.

Engage your team in the game of reaching the goal. To know the score (and win the game) you need to SHOW the score. Don’t play hide and seek with your sweet scorecard. Share it with your team so that they can help reach the taproom goals.

You’ve got the intel, and you’ve got the taproom, get out there and build an awesome scorecard today.