By: Raj Tulshan, Founder of Loan Mantra

They say money can’t buy happiness, but it can help create peace of mind by alleviating stress in professional life – especially if you’re a business owner! Professional financial freedom means taking control of your finances and amassing enough cash and savings to manage daily operations, handle emergencies, drive growth, expand and maybe even sell the business one day.

For beverage business owners, knowing that payroll can be met, a second location of your bar or location could be opened, staff and vendors can be paid – and there is still enough money set aside for any emergencies can provide stability. We’re all familiar with certain strip malls or vacant locations where different businesses seem to come and go, unsuccessfully. In contrast, towns and cities are identified by the bars, pubs and restaurants that are landmarks, meeting spots and seen as a local staple in their areas.

Financial freedom offers a variety of benefits that go beyond financial control. A recent study by Harvard Business School found that having more money reduces intense stress, brings greater control, and leads to higher life satisfaction. Other benefits of financial freedom include improved mental health, better relationships, more opportunities, an elevated lifestyle and greater independence.

The path to financial freedom. We all want financial freedom so how do you get there?

Become a business owner. Simply becoming a business owner provides an essential freedom that can’t be explained unless you are one. As countless entrepreneurs attest, many people prefer to work for themselves rather than for someone else because they have more control over their future – and their finances. A Baylor University professor found that despite the challenges of business ownership – including long hours and high stress levels – entrepreneurs report consistently higher rates of happiness vs. people who work for others.

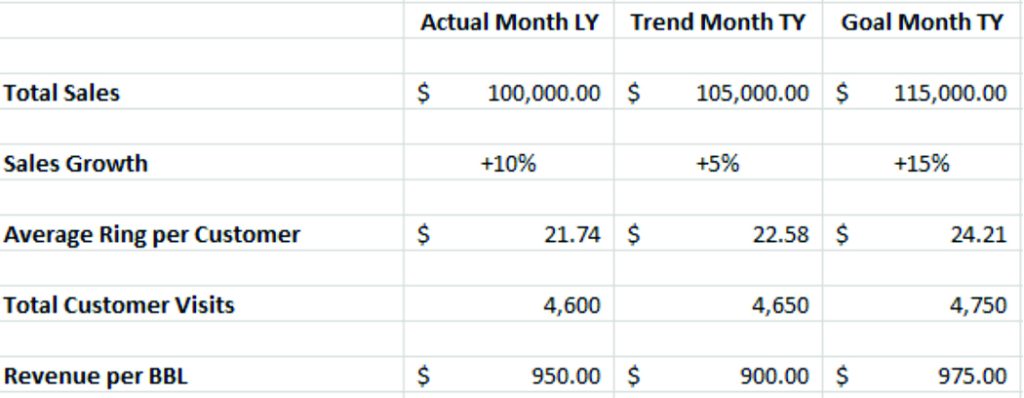

Create a budget. Develop and stick to a budget. Outline operating income, receipts, expenses, loans, rent/mortgage, insurance, utilities, payroll, supplies, equipment, etc. Carefully track spending to account for every dollar. Negotiate where possible, switch vendors or gain better rates for your phone and cable services. Determine which of your products are the best (and worst) sellers and adjust stock accordingly.

In addition to tracking budget, there are common questions each business owner should ask themselves to manage their financial health. For instance, do you have outstanding accounts? Do your clients pay on time? Have you spoken with your top clients in the past 90 days? Do you have your documentation prepared in case you need to apply for a loan? Loan Mantra’s financial health checklist is a great tool to monitor ongoing questions that will not only help you track your budget, but your continued success.

Make it “to go” and be in the know. A report released in June 2023 by the National Restaurant Association found that more than half of millennials (62%) and Gen Z adults (52%) would pick a restaurant for takeout if alcohol beverage options were included. Currently only ¼ of adults order alcohol beverages online due to availability or state legislation, but that is changing leaving room for opportunity. It’s also important to know the upcoming industry trends. For example, that same report states that it reaffirms the associations predictions that local experiences would be this year’s hottest trends – 79% of beer drinkers would participate in a tasting event at a restaurant.

Establish authentic customer relationships. According to the US Chamber of Commerce nearly everyone has been affected by Covid Fatigue over the past couple of years leaving people emotionally drained and physically worn out. As a result, consumers want their shopping and dining experiences to be easy, convenient and satisfying. Satisfied customers are repeat customers. In addition, customers are looking for a deeper emotional connection and a personalized experience.

Use digital media. For brands to build and maintain customer loyalty, the digital experience matters but it must not make things more complicated for the consumer. Whether a customer is ordering online or on-site it must be intuitive and easy. People find the new hottest brew, bar or pub on social media so having a presence online is a must. Post images of the business with indoor/outdoor dining space, food and drinks. Post happy hours, specials, trivia nights, special tastings, etc. and publicize them. Encourage satisfied customers to leave reviews. Allow customers to order food or make reservations online. Make services like DoorDash or OpenTable available.

Be frugal. Consider how business magnate, investor, and philanthropist Warren Buffett purchased a $31,500 home in 1958 and still hasn’t moved out of it, even though his net worth is currently $104 billion. He can obviously afford a bigger, more expensive house, but he’s famously frugal. Conversely, controversial rapper and designer Kanye West is known for his extravagant lifestyle. He lives in a $20 million mansion – and rented Madison Square Garden for a stunt with his clothing line – despite being $53 million in debt. In a bizarre move, he asked Facebook founder Mark Zuckerberg for $1 billion on Twitter.

This is clearly an extreme example, but it shows how financially responsible Buffet amassed a tremendous fortune and achieved financial freedom, whereas financially irresponsible West spent money he didn’t have, wound up in massive debt, and begged a tech guru for a financial handout on social media. While you’re likely not in the same tax bracket as mega-successful billionaire entrepreneurs, you can learn a few lessons from them. Don’t spend more than you have. And keep your endgame in mind. It may be easier to save money when keeping your eyes on the prize.

Invest. Go for a long, slow simmer vs. a quick sear. Most investments are like an Italian grandma’s Sunday sauce – they need to simmer for a long time to be any good. Know that you’ll be in it for the long haul. This won’t be a quick sear type of situation, where your money will be tied up only for a short time. While there’s always some risk and market fluctuations involved in investments, putting some of your available funds toward stocks, bonds, mutual funds, Roth IRAs, 401(k)s and other investment opportunities can help grow your wealth and put you on the path to professional financial freedom. Talk to a financial expert about how to build an investment portfolio and choose the investments that will best fit your specific goals.

Focus. Focus on factors you control. Over the past few years, we’ve seen headlines about banks collapsing, an impending recession, plummeting stocks, and other doomsday stories about how our financial futures are in crisis. Don’t panic. Everything that’s happening today is just part of the normal economic cycle. There will always be recessions, wars, and fluctuating interest rates. Take a deep breath. Unemployment is down. Banks are protected. There’s been recession chatter for years, and it hasn’t happened. Prices and the stock market will fluctuate over time, which is out of your control. Focus on what you can control on your path to professional financial freedom: creating a budget, saving money, and investing.

Have an emergency plan. Create an emergency plan, ensuring that you have enough savings to cover daily and unexpected business expenses. Without adequate funding in place for emergency expenses (the air conditioning breaks, the plumbing isn’t working, the roof leaks), as well as for the inevitable periods of higher spends (e.g. extra products and staffing around the holidays, etc.), you’ll get stuck in a cycle of borrowing to fund necessary operating expenses or to repair what has been damaged, rather than using capital to look ahead to the future.

Find financial partners. Who is your banker, attorney and loan officer? Does the banker have a vested interest in your community? What are the financials? Does the bank have good leadership? Do you have an attorney in case you need legal advice, or someone should make a claim against your business? What about a loan officer or provider? If you need assistance with funding to cover the business in a pinch, to handle an expansion or to keep you aware of current government subsidies that you might take advantage of.

Having the right partners in place before you need them can mean the difference between a quick phone call and financial mayhem. Find a financial team that will be trustworthy, provide insight and are available when needed.

You should have complete confidence in their knowledge, experience and capabilities. Talk to them about your business financial status and goals and create a financial plan to help you achieve financial freedom and long-term financial health.

“For business owners, becoming financially free is a desirable – and achievable – goal,” Tulshan explained. “It takes dedication, determination, and consistency, but follow these tips and you will be well on your way to financial independence.”

About the Author

Neeraj (Raj) Tulshan is the founder and managing partner of Loan Mantra, a one-stop FinTech platform that democratizes the loan process by providing corporate sized services and access to new entrepreneurs, small and medium sized businesses.