Another year, another resolution.

By Hanifa Sekandi

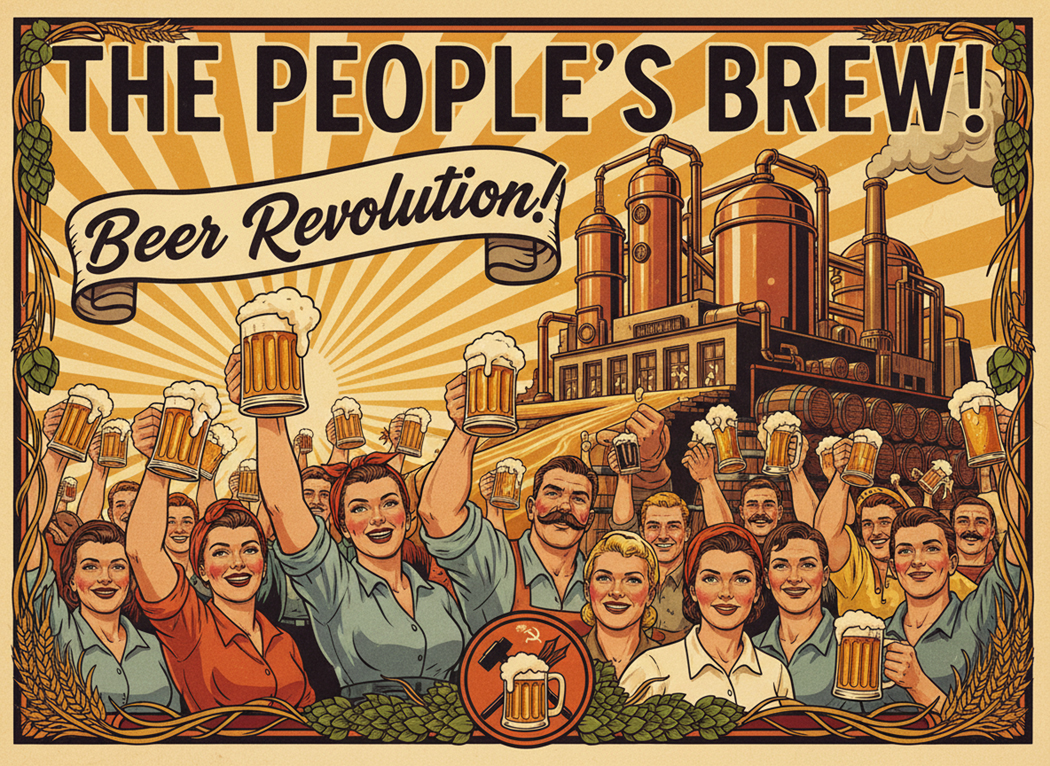

What are your brand’s goals this year? What do you want to achieve? Did you meet your goals last year? When most people think about a New Year’s resolution, they think about personal goals and solutions to improve their lives. Your brand is always looking for fresh solutions. It may be a complete revolution—an overhaul of what once was for something new and inspiring.

The beauty of this time of year is that it forces everyone to dig a little deeper and think critically about what kind of impact they would like to have. Seeing your brand as a movement, a cultural wave that people desire to be a part of, will allow you to see your consumers authentically. Understanding how your beverage fits in their lifestyle, their personal brand ethos, particularly for those who imbibe mindfully.

As you draft this year’s creative brief and refine your band guidelines, change your approach. As a team, come together and create a resolution board. A visual tool that will allow you to dream up ways to be an industry disruptor in the best way possible. Think big and be bold. Include places around the world that inspire you, food, culture, fashion, and every facet of life that will help your beverage become more than just another drink, but a lifestyle brand.

This allows you to see your brand in motion. Perched on a table at a cafe by the beach or poured while dining on a gourmet meal at a high-end restaurant in Paris. While you create this vision, do not think about trends. You are the trend; you are the movement. When you visualize your brand this way, you will not get lost in the race because you will focus on who is running next to you. Also, remember, having a community of other beverage brands is important. Do not compete, disrupt.

The Shift is Possible

It is easy to believe that, as a brand, you are stuck. The notion that you need to move full steam ahead with the way things are and have always been. Why would you purposely implement a brand shake-up? What about all the time, money, and effort spent on past initiatives? Should you abandon them? Remember, you are always stacking your brand wheel. Even during a brand revolution, you keep elements that have worked for your brand. It is not a complete elimination of everything.

A good example is when you decide to embark on a wellness journey. Yes, you are shedding parts of yourself, but the good parts remain intact. It also allows the best parts of you to shine. We often hide the best parts of ourselves beneath the things we do not like. Brands do this when they refuse to change. They refuse to make bold moves that, eventually, will prove to be beneficial. Do not change identifying markers that make you unique. Instead, think of ways to take the good and make it impactful.

So how do you get started? How do you make the shift? Look at your product performance. Review campaigns that had a great ROI. Then analyze areas where you missed the mark. Your answers are always found in the steps you have already made. You do not need to hire an agency or consultant to tell you this. A vision board will help you visualize this. This is a visual anchor to remind you of where you want to be or plan to go in the next 5 to 10 years. If you decide to hire someone to help you bolster this vision, you will avoid those who don’t see it and try to convince you to go in another direction.

Not all experts are gold stars. Even great advice can be bad advice. So many people had great ideas but then were steered away from them because they trusted someone else’s vision. Your vision was planted in your heart for a reason. So, remain clear and steadfast. Stay the course, like the best of the best who were beverage innovators of their time.

You’re Not Stuck

Once you have decided to make the shift and start devising a plan to make your beverage stand out, do not limit your possibilities. You are never stuck; you are just afraid. People often confuse fear with being stuck. With limited budgets or teams, it can appear this way. Fortunately, we live in a world where communication is at your fingertips. Your entry into the market is made easier, and barriers can be overcome.

Did you know that the founders of Airbnb first started their business by renting air mattresses to pay their rent? Or that John Schnatter, the founder of Papa John’s, started with rented equipment in a broom closet, his goal was to make enough money to date? You could be the next Ben Weiss, who launched his beverage brand Bai in his basement. His brand was acquired for $ 1.7 billion. When there’s money, there’s a way, of course, but when there is a WILL, there is a way.

The problem most people face is that they are not running their own race. Competition will always exist. Consumers will always have choices. Spending your time worrying about this will set you back. Look ahead and be thankful that the market exists. Imagine a world where only one beverage existed. Only one flavor by one brand. Life would be quite boring. Like nature, a forest full of trees is a forest full of trees, each with a unique story and distinct markings. Your beverage is a tree in that forest, and the people going on a hike through it will see you. They want to know what your story is and how you contribute to the beverage ecosystem.

Start the Beverage Revolution

It is exciting to think that there is a founder somewhere crafting a new beverage idea from their kitchen. It is exciting to know that there are beverage brands that are bold enough to try something new, to be the rebels of the beverage industry. What do you have to lose? There is so much to gain if you approach this with a fearless mindset. There are so many reasons why you should not start. If you ever ask someone in the beverage industry, they will often tell you all the reasons why it is a bad idea.

Isn’t it funny that someone who is doing something you desire deters you? You can see this as an opportunity to propel yourself forward into the unknown and write your own beverage brand story or give up. Look back and realize the what ifs you had control of.

What if you tried? What if you did things a little differently? What if their story is not your own?

No one will know unless you try. What is in a world-class beverage brand is the person who believed in their product. That never doubted that theirs is nothing like the others, just one sip, taste buds enlivened, and an industry transformed by you and your beverage.